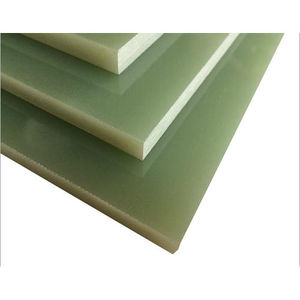

Technical data sheet g 10 is a fiberglass epoxy laminate usually specified when extremely high strength and consistent dimensional stability over tem perature is required.

G10 fiberglass sheet australia.

It has characteristics of high strength excellent electrical properties and chemical resistance not only at room temperature but also under humid or moist conditions.

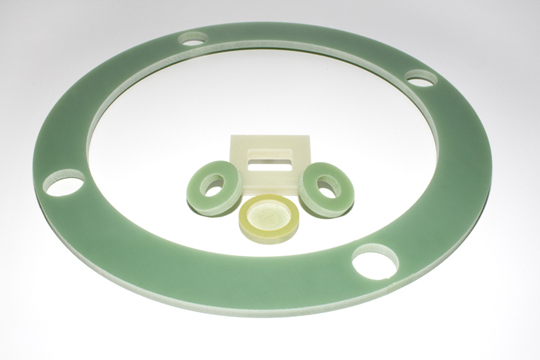

G 10 is used for terminal boards high humidity applications electrical and electronic test equipment and electric rotor insulation.

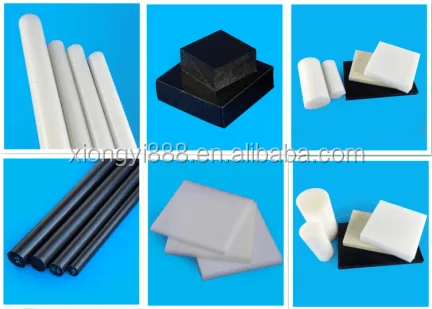

This material is very light but also very strong and stable.

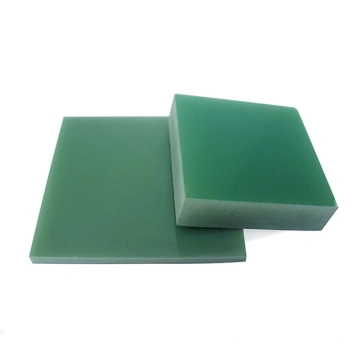

We produce these in both solid colors and multicolored layering.

G10 liner material eliminates the hygiene and swelling issues caused by vulcanized fibre.

G 11 is used for terminal boards high humidity applications electrical and electronic test equipment and electric rotor insulation.

G 11 is difficult to cut or machine and may require special equipment.

Can be cut shaped drilled taped machined and polished with ordinary tools.

Garolite g 10 fr4 sheets and bars a good all around choice these garolite g 10 fr4 sheets and bars are strong machinable and electrically insulating.

300x335x3mm black g10 fr4 epoxy fiberglass composite sheet panel 11 8 x 13 inch.

5 0 out of 5 stars 2.

An incredibly strong material g10 is the material of choice for hard working and heavy duty knives.

Free shipping by amazon.

Coloured g10 can look fantastic on the right project.

This glass epoxy laminate is specified for its extremely high strength and high dimensional stability over temperature.

G 10 is slightly stronger while g 11 is a better insulator and can.

Overview of g 10 fr 4 sheets g 10 fr 4 is a thermosetting industrial laminate consisting of a continuous filament glass cloth material with an epoxy resin binder.

Therefore fr4 can be safely substituted where g10 is called for while g10 can never be substituted where fr4 is called for.

Get it as soon as sat sep 19.

The most versatile all around laminate grades are continuous glass woven fabric impregnated with an epoxy resin binder.

The main difference between nema grades g10 and fr4 is that fr4 is a fire retardant grade of g10.

They re made of a flame retardant epoxy resin with fiberglass fabric reinforcement.

G10 can be sand blasted to create a fantastic textured finish.

Epoxy resins are among the most versatile and widely used plastics in the.

G10 meets mil i 24768 2 gee and fr4 meets mil i 24768 27 gee f.

Fiberglass sheets g9 g10 fr4 glass epoxy sheet g10 and fr4 glass cloth reinforced epoxy natural is typically a yellowish to light green color.