Monroe nor any of its employees shall be held liable for any improper or incorrect use of the information described and or contained herein and assumes no responsibility for anyone s use of the information.

Gauge sheet metal definition.

In the u s the thickness of sheet metal is commonly specified by a traditional non linear measure known as its gauge.

1 for sheet metal a retrogressive scale higher numbers mean lower thickness that starts with 10 gauge representing a thickness of 3 416 millimeters or 0 1345 inches.

When working with sheet metal the term gauge is often used.

Unit of thickness of a metal sheet or wire.

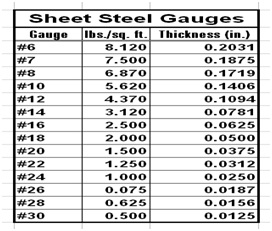

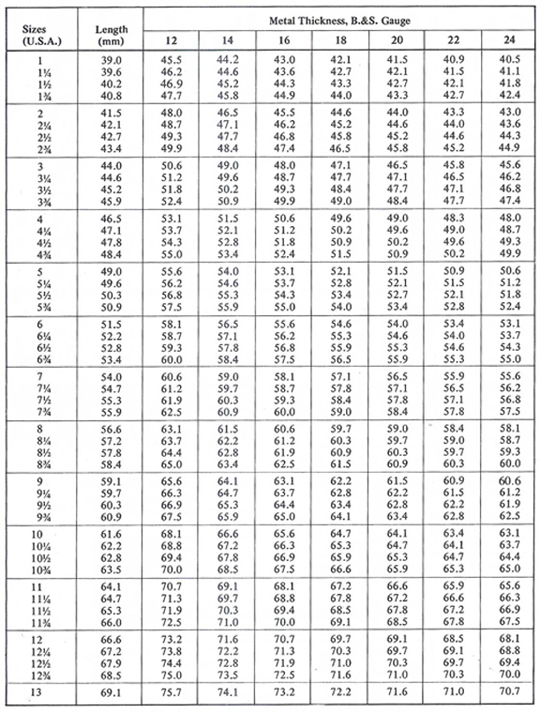

Sheet metal gauges the below table summarizes sheet metal gauge and tolerances.

Gague ga is a length measurement unit for diameters originating in north america and belongs to the browne sharpe metering system.

A sheet metal gauge sometimes spelled gage indicates the standard thickness of sheet metal for a specific material.

As the gauge number increases the thickness drops by 10 percent.

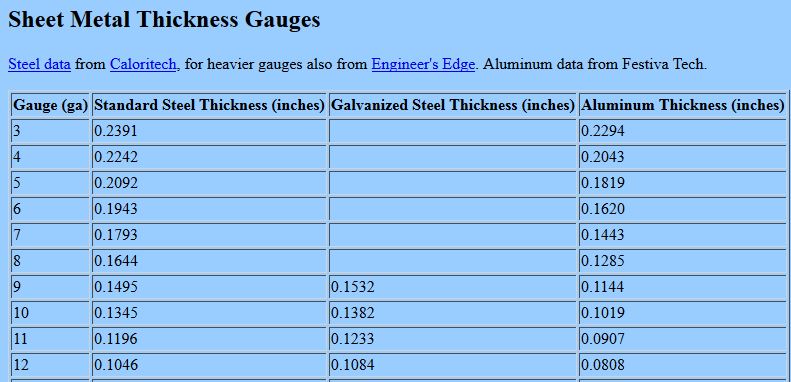

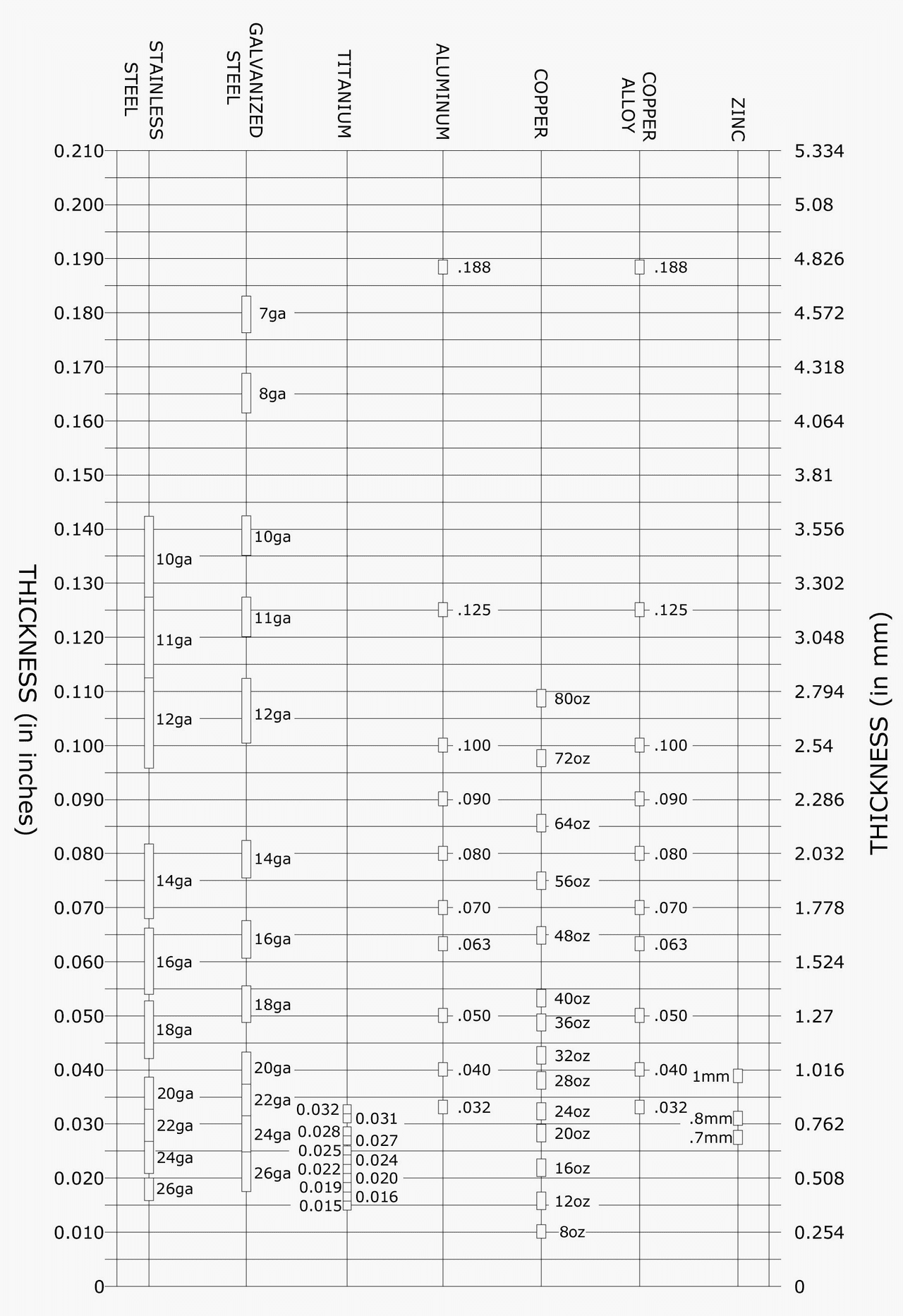

Gauge differs between ferrous iron based metals and nonferrous metals such as aluminum or copper.

Gauge is a dimensionless number sometimes spelled gage and confusingly it works backwards.

Gague are used to specify the thickness of a metal sheet.

Gauge or gage sizes are numbers that indicate the thickness of a piece of sheet metal with a higher number referring to a thinner sheet.

As the gauge number increases the material thickness decreases.

Usually a bigger number means there s more of something but 18 gauge steel is thinner than 16ga not thicker.

Commonly used steel sheet metal ranges from 30 gauge to about 7 gauge.

The larger the gauge number the thinner the metal.

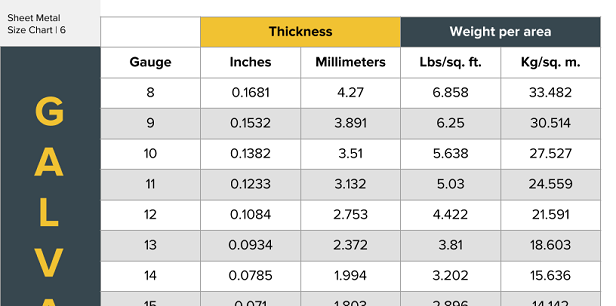

The equivalent thicknesses differ for each gauge size standard which were developed based on the weight of the sheet for a given material.

The manufacturers standard gage provides the thicknesses for standard steel galvanized steel and stainless steel.